Tool Tracking

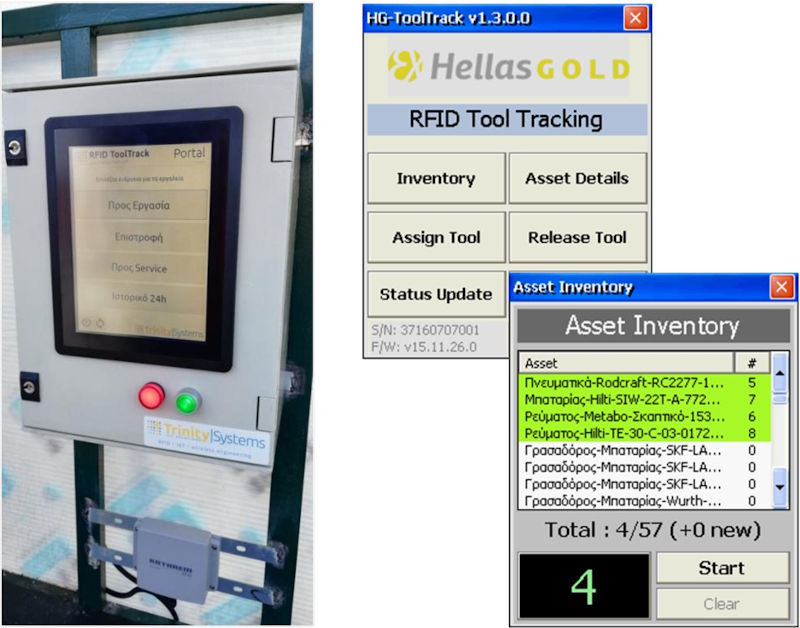

using UHF RFID technologyToolTrack ensures that everyone entering a construction site is properly equipped and no tools are left behind at the end of the day.

How it works

ToolTrack utilizes UHF RFID technology which surpasses barcode in terms of:

remote identification (up to 6m),

no need for visual contact (e.g. tools inside boxes),

excessive resistance to dirt and dust,

speed and accuracy (multiple tag readings in milliseconds).

The system consists of handheld devices, tabletop stations and portals that control storage access and track tools & equipment throughout their daily work-cycle (assignment, operation, maintenance, inventory etc).

Benefits

ToolTrack enables:

automated self-checkout,

accountability for tool condition,

detailed usage analytics,

stock rotation to prevent tool wear and degradation,

regular inspection based on actual usage,

fast and accurate inventory,

efficient optimization of MRO (Maintenance, Repair and Overhaul).

Who can benefit

Construction sites

Mining industries

Oil and gas rigs

Companies with intense maintenance & repair needs